All our fabrics are made in the Prato Textile District—within 8 kilometers of our headquarters—through long-standing partnerships with skilled artisans and highly qualified manufacturers.

This proximity and integration benefit every part of our company—design, R&D, production, and quality—so, season after season, we turn shared know-how into fresh proposals and bespoke developments tailored to clients’ briefs.

Guided by continuous research, we ensure that our most distinctive developments are recognized and safeguarded when appropriate—always in the service of durability, responsibility, and performance.

Why proximity-based production? Because being physically close lets us follow every stage in real time, understand exactly how each fabric is made, and assess the impact of our work. It is equally crucial in the design phase, where deep knowledge of raw materials—their possibilities and limits—helps us enhance their value and reduce waste.

All our fabrics are made in the Prato Textile District—within 8 kilometers of our headquarters—through long-standing partnerships with skilled artisans and highly qualified manufacturers.

This proximity and integration benefit every part of our company—design, R&D, production, and quality—so, season after season, we turn shared know-how into fresh proposals and bespoke developments tailored to clients’ briefs.

Guided by continuous research, we ensure that our most distinctive developments are recognized and safeguarded when appropriate—always in the service of durability, responsibility, and performance.

Why proximity-based production? Because being physically close lets us follow every stage in real time, understand exactly how each fabric is made, and assess the impact of our work. It is equally crucial in the design phase, where deep knowledge of raw materials—their possibilities and limits—helps us enhance their value and reduce waste.

Elasten® — élin® & BFlex® Technologies

Part of the Milior Group, Elasten® is our center of excellence for yarn elasticization within the Prato Textile District. Its research-driven approach turns natural and technical fibers into high-performance stretch yarns for knitting and weaving.

Two proprietary innovations define this expertise:

• élin® is a patented family of yarns in pure linen, hemp, and ramie/nettle that pairs natural breathability and thermoregulation with a clean, even surface and dependable stretch recovery.

• BFlex®—the latest evolution—achieves elastic performance without an elastomeric component, delivering modern comfort and an unexpectedly smooth, fluid hand across fibers and yarn counts.

By strengthening a short, local supply chain and advancing more sustainable stretch solutions, Elasten® expands our ability to design durable, responsible fabrics.

Elasten® — élin® & BFlex® Technologies

Part of the Milior Group, Elasten® is our center of excellence for yarn elasticization within the Prato Textile District. Its research-driven approach turns natural and technical fibers into high-performance stretch yarns for knitting and weaving.

Two proprietary innovations define this expertise:

• élin® is a patented family of yarns in pure linen, hemp, and ramie/nettle that pairs natural breathability and thermoregulation with a clean, even surface and dependable stretch recovery.

• BFlex®—the latest evolution—achieves elastic performance without an elastomeric component, delivering modern comfort and an unexpectedly smooth, fluid hand across fibers and yarn counts.

By strengthening a short, local supply chain and advancing more sustainable stretch solutions, Elasten® expands our ability to design durable, responsible fabrics.

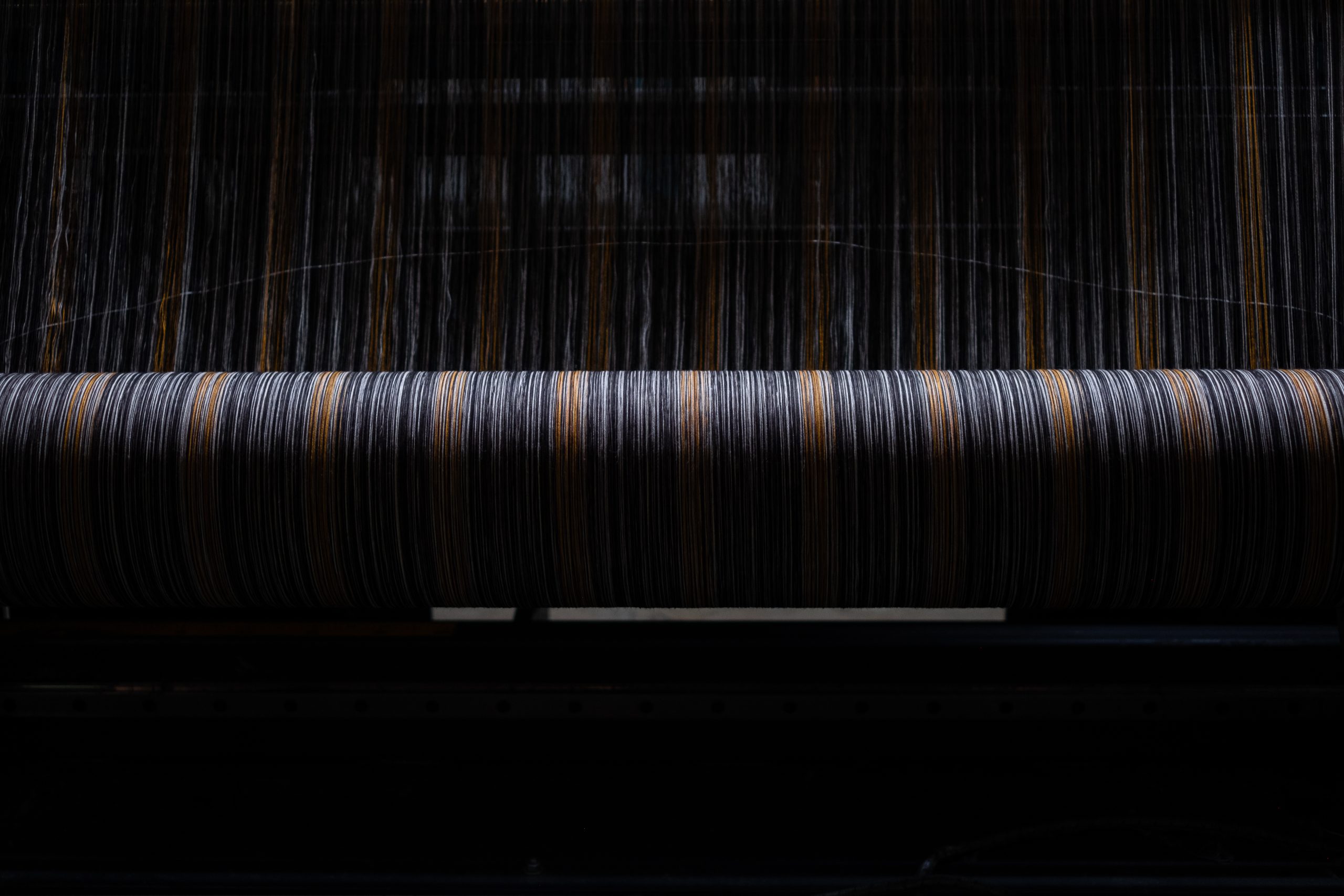

Warping

Within walking distance of our headquarters, Orditura Lena® prepares the warp beams that set fabric quality from the very first meter.

Proximity enables same-day checks, quick fine-tuning and full traceability across fibers and counts. Clean, stable warps keep weaving fast and flawless—an everyday proof of the Milior District, where companies are literally a short walk apart and processes are under real-time control.

Warping

Within walking distance of our headquarters, Orditura Lena prepares the warp beams that set fabric quality from the very first meter.

Proximity enables same-day checks, quick fine-tuning and full traceability across fibers and counts. Clean, stable warps keep weaving fast and flawless—an everyday proof of the Milior District, where companies are literally a short walk apart and processes are under real-time control.

Weaving

This is where warp and weft meet—and Milior fabrics come to life. At Innocenti & Nesi, a historic Prato mill, setup changes and quality checks run alongside production to guarantee tight constructions and the drape our collections are known for. Many of our most iconic fabrics were born here—Tarallo® above all—testifying to decades of shared know-how and craft.

Weaving

This is where warp and weft meet—and Milior fabrics come to life. At Innocenti & Nesi, a historic Prato mill, setup changes and quality checks run alongside production to guarantee tight constructions and the drape our collections are known for. Many of our most iconic fabrics were born here—Tarallo® above all—testifying to decades of shared know-how and craft.

Finishing

The final step elevates the fabric according to each brand’s brief. Through controlled mechanical and functional treatments—heat-setting, sanforizing, emerizing, calendaring, coatings, soft-touch and water-repellent options—we shape hand feel, drape and performance.

Close collaboration turns finishing into an iterative dialogue, refined by testing and roll-by-roll inspection to achieve the exact look, grip and behavior on the body.

Stock service

Our Stock Service warehouse is built for capacity: rows of floor-to-ceiling racks keep a wide range of fabrics ready to ship, enabling fast deliveries and agile prototyping. Among the aisles, designers can uncover curated surplus and off-card gems—perfect for limited drops and capsule collections. A smart, circular way to find characterful materials, shorten lead times, and give existing fabrics a second, brilliant life.